NC State Doctoral Student Developing Better Manufacturing Method for Wound Closures

If you’ve ever gotten stitches or had surgery, you may have had a suture. They’re the threads used to close wounds or join tissues together for other purposes.

But did you know that there are different types of sutures which can have an effect on your experience at the doctor or surgeon’s office?

Barbed sutures, for example, can reduce the amount of time you spend on the operating table and lower the likelihood of surgical complications. That type of suture has its roots in the Triangle and is being advanced by students and faculty at the Wilson College of Textiles.

Dr. Gregory Ruff, a nationally-renowned plastic surgeon, first invented the innovative closure in 1991, just down the road in Chapel Hill, North Carolina.

“I was thinking about the fact that we sew wounds together with a loop and a knot and if you tie it too tight, it can constrict the circulation and kill the tissue in that loop,” Dr. Ruff remembers. “I was thinking about animals, and a porcupine’s quill came to mind. And the aha moment was, ‘What if we put a quill on one side of the wound and another one on the other side of the wound, so there’s no loop the barbs go in but they don’t come out?’”

As the name suggests, barbed sutures have small projections shooting out of them that can latch onto tissues: think about barbed wire or a fishing hook. Those “quills,” or barbs, allow the suture to self-anchor. Since no knot is needed to secure the suture, the closure is faster, and the lack of knots, and constricting loops, promotes healing. This also allows surgeons to schedule more surgeries.

Soon after his aha moment, Dr. Ruff started his own company, Quill Medical, to fabricate these barbed sutures. While he had the medical expertise and a solid business partner, Dr. Ruff was looking for someone who could advise him in terms of the material makeup of the suture. The Wilson College’s Biomedical Textile Research Group, under the direction of Professor Martin King, quickly proved to be the perfect partner.

Using the Wilson College’s labs, King’s graduate students conducted a number of tests on Ruff’s sutures across different types of tissues (such as skin, muscle, etc.). One of those students, Nilesh Ingle, found that the barbed sutures worked best when the angles of the barbs were tailored specifically to the type of tissue being sutured.

Years later, one of King’s current graduate students is building on that research insight.

Understanding challenges and innovating solutions

Nearly three decades after the barbed suture’s invention, the majority of surgeons still use conventional sutures despite the advantages documented by researchers and surgeons. Why?

Karuna Nambi Gowri, a fiber and polymer science doctoral student in King’s research group, says it comes down to two reasons. The first of these is resistance to change. Most practicing surgeons learned how to use a suture before barbed sutures became more broadly available.

Interested in learning more about our Ph.D. Fiber and Polymer Science? Click the video below!

The second obstacle to the use of barbed sutures is procuring them. Barbed sutures tend to be both expensive and low in supply. That’s because the current process for making them (mechanical and blade-based) is inefficient in terms of both time and resources.

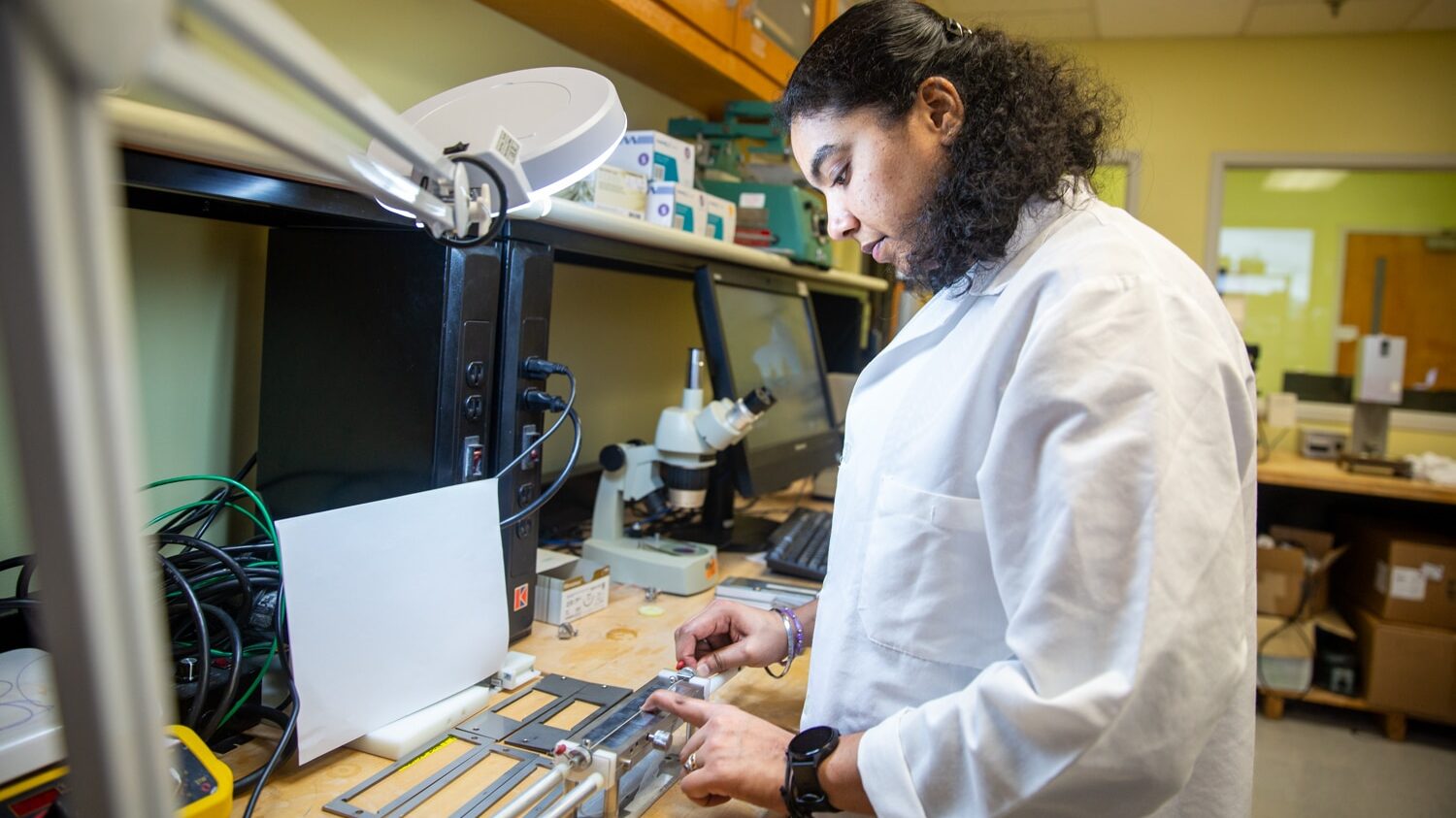

That’s where Nambi Gowri’s research with the Wilson College’s Biomedical Textiles Lab comes in. She’s developing a faster and cheaper method for making the same quality of barbed suture.

“If I fabricate using a laser, the fabrication time is pretty short compared to a mechanical barbing technique,” Nambi Gowri says.

Moving from a mechanical method to a laser method has another advantage.

“The manipulation of the barbed suture itself is easier using a laser,” she says.

In other words, using the lasers will allow Nambi Gowri to apply the custom barb geometries, or angles, suggested by prior researchers on a commercial scale. These custom geometries will allow the barbed suture to be optimized for the type of tissue it will be connecting.

In addition to the new process, Nambi Gowri is also developing a new suture.

“I’m the first one to actually study Catgut barbed sutures,” she explains.

Catgut was actually one of the earliest materials used to make sutures. The filament is made from tissue taken from an animal’s stomach – especially cattle stomachs – hence the name. While the industry had moved away from this material in favor of synthetic polymers, Nambi Gowri sees the potential for catgut in barbed sutures because of their quick degradation rate.

“These are useful external wound closures,” she says. “Because our body contains so much collagen and Catgut is made up of 90% collagen, it’s a more suitable polymer that can be used in human tissue.”

Hands-on experience informs research

In the meantime, Nambi Gowri has gained hands-on experience to inform her research by fabricating all of the barbed sutures used in Dr. Ruff’s micro facelift surgeries.

The surgery itself is made possible because of the shape and the material composition of the sutures: poly 4-hydroxybutyrate (P4HB). This polymer is already present naturally within our bodies, so sutures made from P4HB are naturally and safely absorbed by the body over time. That means patients don’t have to schedule an appointment after surgery for the sutures to be removed.

P4HB also provides the perfect combination of strength and elasticity to hold up the facial tissue until the wound has healed. The barbs, on the other hand, allow for the suture to be placed and stay secure within the skin without the need for large incisions.

“That skin tightens up right away,” Dr. Ruff says of the procedure, which draws patients from across the country. “So I don’t have to remove hair, and I don’t have to put a scar at the hairline.”

“These sutures are not available commercially anywhere in the world. So to be able to mechanically barb different size sutures in a reliable and consistent manner for use in clinical practice, requires skill, experience and knowledge of quality control,” Professor King says of Nambi Gowri’s work.

This has given Karuna a hands-on understanding of the sutures she’s hoping to improve upon.

She says her fiber and polymer science knowledge has played a key role in helping her approach all sides of her research.

“All the analytical characterization techniques that are used for characterization of sutures – like identifying mechanical properties and measuring tensile strength – is actually from my knowledge of textiles,” she says. “I’m applying my polymer chemistry knowledge to make sure that the laser doesn’t cause the sutures to degrade, melt or experience thermal damage.”

What’s next?

As she works to patent her designs, Nambi Gowri feels confident that her dissertation will set her up for success in the research and development (R&D) field after graduation.

In the meantime, she’s already finding out about the ways her research can have a broader impact.

“Dr. Dan Duffy, DVM, a surgeon at the NC State College of Veterinary Medicine is also interested in using barbed sutures to repair torn and failed tendons on his animals, but he finds the cost of buying commercial barbed sutures prohibitively expensive. So we need to collaborate,” King says. “Karuna to the rescue!”

This post was originally published in Wilson College of Textiles News.

- Categories: